از اونجایی که بسیاری از عزیزان با نحوه فعالسازی محصولات شرکت Autodesk از قبیل AutoCAD و 3d'sMAX و ...مشکل دارن تصمیم به ایجاد این تاپیک گرفتم

در این آموزش نحوه نصب و فعالسازی نرم افزار پرکاربرد AutoCAD رو مرور میکنیم

سایر نرم افزارهای این شرکت عموماً به همین شکل قابل فعالسازی هستند

« تمامی مراحل نصب و فعالسازی به ترتیب تصاویر زیر انجام میشوند »

![[تصویر: 45.gif]](http://rozup.ir/up/ms66/admin1/tools/vectorgif/EDAME/45.gif)

بهترین و به روزترین حق شماست

اموزش و دانلود رایگان:بهترین و به روز ترین سایت و جدید ترین دانلود نرم افزار,بازی,کتاب مقالات و پروژه و درسی دانشگاهی و دانش اموزی برای همه سنینبهترین و به روزترین حق شماست

اموزش و دانلود رایگان:بهترین و به روز ترین سایت و جدید ترین دانلود نرم افزار,بازی,کتاب مقالات و پروژه و درسی دانشگاهی و دانش اموزی برای همه سنینبررسی کامل و تصویری لیفان 620 در سال 93

بهترین برنامه های موبایل و کامپیوتر..و پروژهای دانشجویی کلیک کنید با افزایش تحریم ها و فشار های بین المللی علیه ایران ، صنایع و اقتصاد کشورمان ، با امضای هر قطعنامه در آن سوی دنیا ، آسیب پذیر تر می شد تا جایی که با افزایش نرخ دلار و کاهش ارزش ریال ، صنعت کشور آسیب جدی دید و با تحریم مستقیم صنعت خودرو و صنایع وابسته ، شوکی بزرگ به بازار خودرویی کشور وارد آمد و شرکت های سازنده ی خودرو در ایران ، برای نجات از معضلات و مشکلات پیش رو ، به تکاپو افتادند .

آموزش کامل و تصویری نحوه صحیح نصب و کرک محصولات Autodesk

دانلود اخرین ورژن اتوکد نقشه کشی Autodesk AutoCAD 2015 SP2 x86/x64 2015

19/9/1393به روز شد

بهترین برنامه های موبایل و کامپیوتر..و پروژهای دانشجویی کلیک کنید

ه

Autodesk AutoCAD 2015 SP2 مطمئنا مهندسان نقشه کشی و عمران این ابزار را بسیار بهتر از افراد معمولی می شناسند. AutoCad جدای از این نرم افزار در حقیقت یک استاندارد جهانی است. در همه جای جهان اگر قرار باشد نقشه ای کشیده شود ، همه آن را با محصول AutoDesk ترسیم خواهند کرد. برای اولین بار است که در سایت های دانلود فارسی زبان نسخه جدید از این طراح حرفه ای قرار می گیرد. این ابزار را به عنوان هدیه ای ناچیز به مهندسان و طراحان نقشه کشی و عمران تقدیم می کنیم

قابلیت های نرم افزار Autodesk AutoCAD :

- افزایش انعطاف پذیری نرم افزار در مقابل طرح ها و هماهنگ سازی تنظیمات آن ها

- بخش Text Command به صورت چند خط بودن

- قابلیت حاشیه نویسی در کنار نقشه ها

- قابلیت بازیابی فایل های از دست رفته

- قابلیت ترسیم به صورت دو بعدی

- قابلیت ترسیم به صورت سه بعدی واقعی

- قابلیت چرخش 360 درجه ای نقشه ها

- استفاده بسیار آسان تر در این نسخه

- قابلیت ترکیب چارت های Excel و AutoCad

- مدیریت کامل بر روی لایه های نقشه ها

- سازگاری بسیار کامل تر با پردازنده های گرافیکی و به دست آوردن سرعت بالاتر در انجام کارها

-

درباره کولر خودرو

در عصر حاضر دیگر وجود کولر در اتومبیل به عنوان یک وسیله لوکس تلقی نمیشود بلکه کولر اتومبیل به عنوان ضرورتی مطرح میگردد که ضامن استفاده از اتومبیل توام با امنیت و آرامش خاطر است. احتیاجی به توضیح نیست که هنگامی که اتومبیل شما مجهز به کولر باشد، میتوانید با اعصاب آرامتر و راحتتر به رانندگی بپردازید. زیرا هرگز گرمای طاقت فرسا، گازهای خطرناک، گرد و غبار و سر و صدا به داخل اتومبیل شما راه نخواهد یافت. سیستم کولر اتومبیل در واقع از مجموعه قطعاتی تشکیل شده است که پس از نصب برروی اتومبیل، برای فضای داخل کابین تولید برودت دلخواه را مینمایند. کولر اتومبیل با کاهش حرارت و رطوبت داخل کابین به ما کمک مینماید تا رانندگی راحت تری داشته و در طول مسیر از آرامش کافی برخوردار باشیم.

![[تصویر: 45.gif]](http://rozup.ir/up/ms66/admin1/tools/vectorgif/EDAME/45.gif)

سنسور اکسیژن خودرو

سیستم های کنترل موتور کامپیوتری شده کنونی ، مبتنی بر اطلاعات چندین سنسور به منظور تنظیم عملکرد موتور ، آلاینده ها و سایر عملکردهای مهم هستند. در صورتی که این سنسورها اطلاعات دقیقی را ارائه ندهند ، باعث بروز مشکلاتی در عملکرد موتور از قبیل : افزایش مصرف سوخت و تولید آلاینده ها خواهند شد.

یکی از سنسورهای مهم در این سیستم ، سنسور اکسیژن است و از آنجایی که فرمول شیمیایی اکسیژن O2 می باشد ، اغلب آن را سنسور O2 می گویند. (لازم به ذکر است که اتم های اکسیژن همواره به صورت جفت ( دوتایی ) حرکت می کنند. )

اولین سنسور اکسیژن در سال 1976 بر روی VOLVO 240 به کار رفت. پس از آن هنگامی که قوانین مربوط به آلاینده ها در ایالت کالیفرنیا کاهش این مواد مضر را لازم دانست ؛ خودروهای موجود در کالیفرنیا در سال 1980 از این سنسور استفاده کردند. کمی بعد قوانین فدرال در مورد آلاینده ها ، نصب سنسور اکسیژن بر روی تمامی خودروها و کامیون های سبک ساخته شده در سال 1981 اجباری کرد و حالا با وجود آیین نامه OBD II ، ( خودروهای ساخته شده از سال 1996 تا کنون ) برخی از خودروها به چند سنسور اکسیژن مجهزاند که در تعدادی از آنها چهار سنسور اکسیژن به کار رفته است.

![[تصویر: 45.gif]](http://rozup.ir/up/ms66/admin1/tools/vectorgif/EDAME/45.gif)

مقاله ترجمه شده رایگان مکانیک خودرو درباره سیستم تعلیق (قسمت دوم)

Dampers: Shock Absorbers

Unless a dampening structure is present, a car spring will extend and release the energy it absorbs from a bump at an uncontrolled rate. The spring will continue to bounce at its natural frequency until all of the energy originally put into it is used up. A suspension built on springs alone would make for an extremely bouncy ride and, depending on the terrain, an uncontrollable car.

Enter the shock absorber, or snubber, a device that controls unwanted spring motion through a process known as dampening. Shock absorbers slow down and reduce the magnitude of vibratory motions by turning the kinetic energy of suspension movement into heat energy that can be dissipated through hydraulic fluid. To understand how this works, it's best to look inside a shock absorber to see its structure and function.

|

|

A shock absorber is basically an oil pump placed between the frame of the car and the wheels. The upper mount of the shock connects to the frame (i.e., the sprung weight), while the lower mount connects to the axle, near the wheel (i.e., the unsprung weight). In a twin-tube design, one of the most common types of shock absorbers, the upper mount is connected to a piston rod, which in turn is connected to a piston, which in turn sits in a tube filled with hydraulic fluid. The inner tube is known as the pressure tube, and the outer tube is known as the reserve tube. The reserve tube stores excess hydraulic fluid.

When the car wheel encounters a bump in the road and causes the spring to coil and uncoil, the energy of the spring is transferred to the shock absorber through the upper mount, down through the piston rod and into the piston. Orifices perforate the piston and allow fluid to leak through as the piston moves up and down in the pressure tube. Because the orifices are relatively tiny, only a small amount of fluid, under great pressure, passes through. This slows down the piston, which in turn slows down the spring.

Shock absorbers work in two cycles -- the compression cycle and the extension cycle. The compression cycle occurs as the piston moves downward, compressing the hydraulic fluid in the chamber below the piston. The extension cycle occurs as the piston moves toward the top of the pressure tube, compressing the fluid in the chamber above the piston. A typical car or light truck will have more resistance during its extension cycle than its compression cycle. With that in mind, the compression cycle controls the motion of the

vehicle's unsprung weight, while extension controls the heavier, sprung weight.

![[تصویر: 45.gif]](http://rozup.ir/up/ms66/admin1/tools/vectorgif/EDAME/45.gif)

اموزش مقاله ترجمه شده رایگان مکانیک خودرو درباره سیستم تعلیق قسمت اول

How Car Suspensions Work

When people think of automobile performance, they normally think of horsepower, torque and zero-to-60 acceleration. But all of the power generated by a piston engine is useless if the driver can't control the car. That's why automobile engineers turned their attention to the suspension system almost as soon as they had mastered the four-stroke internal combustion engine.

Photo courtesy Honda Motor Co., Ltd.

Double-wishbone suspension on Honda Accord 2005 Coupe. See more car suspension pictures.

The job of a car suspension is to maximize the friction between the tires and the road surface, to provide steering stability with good handling and to ensure the comfort of the passengers. In this article, we'll explore how car suspensions work, how they've evolved over the years and where the design of suspensions is headed in the future.

If a road were perfectly flat, with no irregularities, suspensions wouldn't be necessary. But roads are far from flat. Even freshly paved highways have subtle imperfections that can interact with the wheels of a car. It's these imperfections that apply forces to the wheels. According to Newton's laws of motion, all forces have both magnitude and direction. A bump in the road causes the wheel to move up and down perpendicular to the road surface. The magnitude, of course, depends on whether the wheel is striking a giant bump or a tiny speck. Either way, the car wheel experiences a vertical acceleration as it passes over an imperfection

![[تصویر: 45.gif]](http://rozup.ir/up/ms66/admin1/tools/vectorgif/EDAME/45.gif)

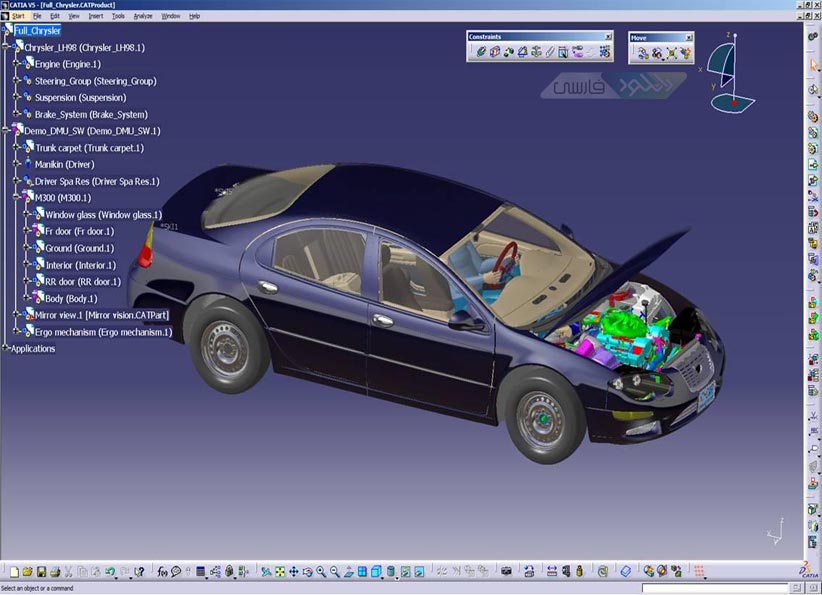

دانلود اخرین ورژن نرم افزار کتیا CATIA V5-6R2013 P3 GA x86 x64

.:: قوی ترین نرم افزار طراحی، مهندسی و تولید با کمک کامپیوتر + Documentation های برنامه ::.

نرم افزار CATIA نرم افزاری قوی برای طراحی به کمک کامپیوتر (CAD)، مهندسی (تحلیل) به کمک کامپیوتر (CAE) و ساخت به کمک کامپیوتر (CAM) از سیستمهای مطرح روز دنیا در صنایع هوافضا (هواپیما سازی)، دریائی، عمران (ساختمانی)، خودرو سازی، طراحی سازه، ادوارات صنعتی، کارخانجات لوازم خانگی و … که از این نرم افزار در پرسه های طراحی صنعتی خود استفاده می کنند. از نتایج استفاده این نرم افزار میتوان کاهش زمان طراحی، کاهش خطا در طراحی، بهینه کردن طرح، کاهش زمان تولید، افزایش کیفیت محصول و افزایش سود دهی را نام برد. در ایران این نرم افزار ابتدا توسط شرکتهای خودروسازی ایران خودرو و سایپا خریداری شد. پس از یاد گیری این نرم افزار توسط مهندسین این شرکتها این نرم افزار به محبوب ترین نرم افزار مهندسی کشور در میان مهندسین و دانشجویان مبدل شد به طوری که هم اکنون از این نرم افزار در صنایع مختلف در ایران استفاده می شود. کتیا ویرایش 5 یک یکپارچگی مناسب و قدرتمندی بین منابع انسانی و ابزارها و روشها و منابع های طراحی، مهندسی و ساخت در یک فرآیند کامل را ایجاد میکند. از توانمندیهای برجسته دیگر این نرم افزار: پرورش خلاقیت و نوآوری، به اشتراک گذاشتن دانش فنی در فرآیندها، ارتباط مستقیم بین طرح سه بعدی مجازی و محصول واقعی و کاهش حلقه های طراحی و ساخت را نام برد. همچنین از دیگر ویژگیها میتوان قابلیت جابجائی آسان و سریع بین محیط ها، سرعت بالای واکنش نرم افزار در برابر عملیات صورت گرفته، مدیریت بر فعالیتهای مربوط به طراحی، خروجی با فرمتهای مختلف، قابلیت تبادل اطلاعات بین دیگر نرم افزارهای CAD و حتی کاربر میتواند یک محیط دلخواه کاری با آیکونهای مورد نیاز خود، طراحی کند.

![[تصویر: 41.gif]](http://rozup.ir/up/ms66/admin1/tools/vectorgif/EDAME/41.gif)

درباره موتورهای شش زمانه

با توجه به طراحی فنی و مکانیکی، موتور شش زمانه همانند موتورهای احتراق داخلی می باشد. اگر چه سیکل ترمودینامیکی و یک سر سیلندر اصلاح شده همراه دو اتاق اضافی ان را به کلی متمایز می کند. یک محفظه ی احتراق و یک محفظه ی تراکم( گرمکن هوا) هر دو از سیلندر جدا هستند. احتراق درون سیلندر رخ نمی دهد اما در محفظه ی احتراق کمکی هم فوری روی پیستون اثر نمی گذارد و زمان ان از 180 درجه ی چرخش میل لنگ، در زمان انفجار(کار) جدا می باشد.

محفظه ی احتراق به طور کلی توسط محفظه ی گرمکن احاطه شده است. با تبادل گرما از طریق دیواره های محفظه ی احتراق که با محفظه ی گرمکن در ارتباط است، فشار محفظه ی گرمکن افزایش می یابد و قدرت مکملی برای کار تولید می شود.

![[تصویر: 45.gif]](http://rozup.ir/up/ms66/admin1/tools/vectorgif/EDAME/45.gif)

آشنایی کامل با موتور اتومبیل به زبان ساده همراه با تصویر انیمیشن

دانلود بهترین برنامه های موبایل و کامپیوتر..و پروژهای دانشجویی کلیک کنید

آشنایی با موتور اتومبیل به زبان ساده همراه با تصویر

آیا تا بحال کاپوت اتومبیل را بالا زده اید و نگاهی به درون آن انداخته اید؟

درون اتومبیل با آن قطعات ، لوله ها و سیم ها واقعا” شلوغ و گیج کننده

به نظر می رسد. آیا می خواهید دربارهء نحوه کار موتور و دیگر بخش های

اتومبیل بیشتر بدانید؟

اگر جوابتان مثبت است ، همراه ما باشید تا نگاهی به دنیای درون اتومبیل ها بیندازیم.

۱ ) موتور :

مهم ترین بخش اتومبیل ، موتور آن است. نیــــروی لازم جهت حرکت اتومبیل با احتراق سوخت (بنزین – گازوئیل – گاز ) در داخل موتور و تبدیل آن به نیروی مکانیکی تامین می شود.

موتورها تعدادی سیلندر (معمولا” ۴ سیلندر) دارند که احتراق سوخت ، آنجا صورت می گیرد. همانطوری که در شکل زیر مشاهده می کنید، داخل هر سیلندر پیستون متحرکی وجود دارد که توسط شاتون به میل لنگ متصل است.

**دانلودبهترین و تنها برنامه اموزش کامل خودرو در برنامه(( اندروید همراه مکانیک حرفه ای شو خودرو))

اموزش قطعات خودرو+تعمیرو عیب یابی خودر+اموزشهای عمومی خودرو+فیلم های

اموزشی خودرو در برنامه(((در مکانیک حرفه ای شو(خودرو))) ....برای دانلود از لینک کلیک کنید

![[تصویر: 19.gif]](http://rozup.ir/up/ms66/admin1/tools/vectorgif/EDAME/19.gif)